Production of Electric Cabinet

We bring energy to your machines. For more than 10 years now, we’ve been producing reliable low voltage control and power electric cabinets for customers in various industries like automotive, metallic, plastics, transportation, foundry, construction, printing, pharmaceutical, tobacco and environmental.

Electric cabinets made by EUROSOFT-Control are used around the world in BMW, VW, Honda, Audi or Porsche factories.

By agreement we are able to ensure production at a partner company with UL508A certification.

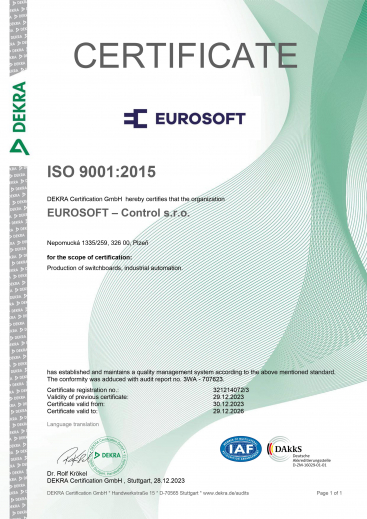

The company EUROSOFT-Control Inc. has an established quality management system and is certified according to the ISO 9001: 2015 standard with the German DAkkS accreditation.

ISO certification area: Design and production of electrical cabinets, distribution selling.

-

Open communication

We advise you when we see the potential for improvement.

-

Speed and reliability

We usually deliver electric cabinets in 5 weeks.

-

Fair approach

We keep the price set at the beginning.

Production process

-

1. Quote

We look at your electrical engineering designs or you describe your requirements to us, and we'll give you a quote. We either get production components ourselves, or you can supply them to us.

-

2. Production

We start the production according to the design. Fitters install selected components in the cabinets and connect them according to the electrical engineering designs.We provide painting at customer's request. We use the RAL or Munssel colour scales.

-

3. Testing

All completed switchboards are tested according to EN 61439. We also perform a functional test of the electric cabinet if required.

-

4. Hand-over

For easy launch, we create and upload hardware configuration into the control system, visualization, or parameters to the appropriate devices.

Why should you choose EUROSOFT-Control?

Tens of satisfied customers

Tens of satisfied customers

Thanks to our diligence and willingness to bring all the projects up to the end, many business partners have promoted us from the subcontractors to the major suppliers. We are reliable and experienced partners for your business.

We meet your requirements

We meet your requirements

We build every device to comply with regulations as well as internal business standards and your end customers’ requirements.

We work diligently and use quality components of renowned manufacturers such as Siemens, Eaton, Rittal, LAPP, Allen-Bradley, Phoenix Contact, Weidmüller, etc.

We test the result machine

We test the result machine

We perform testing according to the EN 61439 standard before we ship the completed electric cabinet to you.

We also perform a functional test of the electric cabinet. We can create and upload a hardware configuration to your control system for easier launch.

We prepare the control system

We prepare the control system

We also offer a control system preparation - software upload to CPU, firmware update, parameter sets upload, e.g. to frequency inverters, and functional test.

We deliver all over the world

We deliver all over the world

We deliver control for your end customer wherever it’s needed. Our experienced technicians are also able to install, start and optimize the machine operation if necessary.